8 Major Modern Aquaculture Construction Machinery and Equipment Needed for Aquaculture Projects

Have you been seeking a simpler and faster way of carrying out our aquacultural construction projects? Then you will have to mind the types of construction equipment or machinery you resort to.

In the past, construction projects within the field of aquaculture were way too tedious and difficult to implement because they had to be done just with the small manual tools available in that era. Deforestation, Leveling, digging, and other site preparation activities had to be done manually, by use of light construction tools/equipment (like pick-axes, wheelbarrows, spades, shovels, buckets, machetes, etc.).

Nowadays, with the advent of technology, there are lots of modern pond construction machinery available on the market to help aquaculture engineers carry out very tedious tasks, much more easier and faster. These machinery range from handheld to heavy-duty machinery needed throughout the pond construction process, from the felling of the trees on the construction site, site leveling, and grading, right up to compaction of the road paths and construction ponds and buildings. Some of these include:

- tree puller;

- feller buncher;

- excavator;

- bulldozer;

- backhoe;

- trencher;

- compactor;

- grader

We are going to walk you through the major modern construction equipment/ machinery that will help you achieve your project goals.

A. Machinery for deforesting the pond construction site

1. Tree puller:

Earthen pond construction requires soil that is completely root-free to avoid any eventual water loss by infiltration through root holes. Therefore all trees should be off-rooted and any remaining broken roots traced and removed from the bottom or dike of ponds. Tree pullers are a choice of heavy-duty equipment used to off-root old tree trunks and short trees to give room for pond construction.

It is mostly used in a site where trees are many and manual digging is tedious – especially if there is not enough time to allow for tree roots to decay before digging earthen ponds.

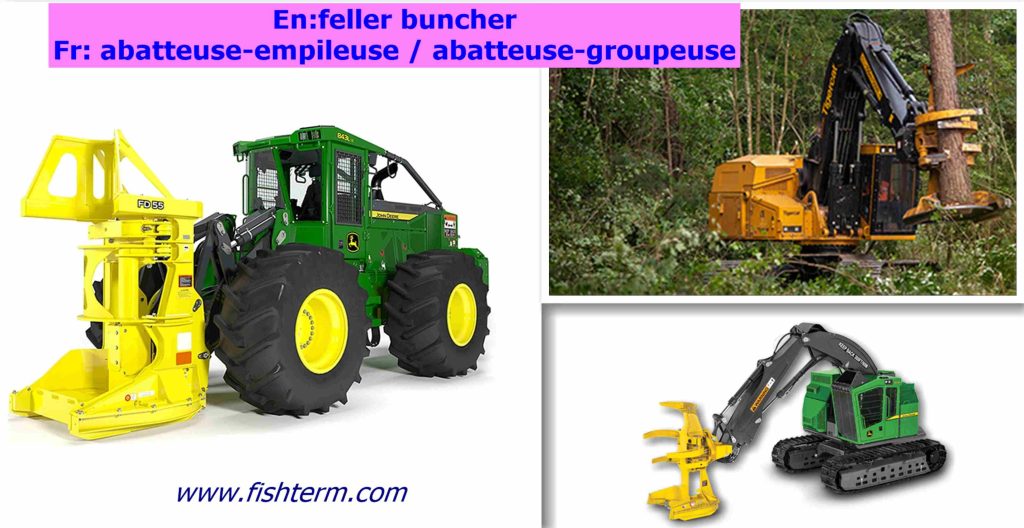

2. Feller Buncher:

Feller bunchers are harvesters with a standard four-wheel base and a chainsaw required for logging and felling of trees. They can be wheeled or tracked, and the choice of which to use depends on the location of the pond construction site. Working with old-growth forests will require a track feller buncher and a track tree puller, especially during the rainy season where movement can be pretty difficult.

Their unique base gives them easy access to off-road sites right into the actual pond construction site. During felling, a feller buncher gathers trees by wrapping multiple metal arms around tree trunks and then snipping its base with a chainsaw. It then carries the entire tree out of the construction area to a collection area where the trunks could be transported for wood processing to serve other purposes.

This piece of machinery is needed in aquaculture projects where the forest trees are too tall to be handled by a tree puller machine.

B. Ground leveling, digging, and earth moving in an aquaculture construction site (earthmovers)

3. Bulldozers:

After removing all trees from the site using a puller and a feller buncher, it’s time to clear off all earthy obstacles on the site.

A bulldozer (dozer) is an earth-moving heavy-duty machine equipped with a metal bucket plate used to push, carry, and condense any sort of loose material, usually earth on a pond construction site. Its metal plate can also be used to loosen compacted grounds, hills, or other stable structures. Like pullers and bunchers, dozers come with wheels or a track. Opt for a track dozer for big aquacultural construction projects, which require working in muddy areas.

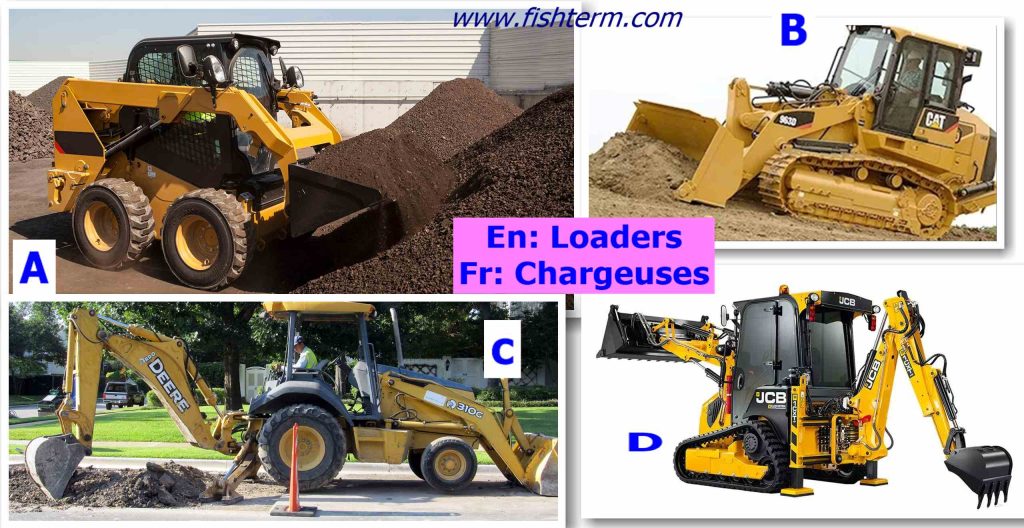

4. Loaders:

Aquacultural loaders come in several configurations with their names varying according to the configuration and/or the tool attachment on their cabins. Below are the popular loaders used in pond construction projects:

Skid steer loader: small engine-powered machine used for a plethora of loading jobs on the site. In front of the operating cabin, there’s a mechanism that allows for the attachment of different types of tools. It can host different equipment ranging from buckets to loaders and is also small enough to maneuver into narrow areas during loading. Skid steer loaders can be tracked(image B), commonly known as tracked loaders, or wheeled(image A), commonly known as wheeled loaders.

Backhoe Loader: Equipped with a backhoe in the back of the cabin, and a bucket in front, this is a multi-purpose machine. Similar to a tractor, it’s used to push and load earth, with the additional benefit of scooping where need be. Backhoe Loaders come with wheels (image C) or tracks (image D). The wheeled backhoe is commonly used in urban environments. Opt for tracked backhoes for construction in muddy sites and forests.

C. Digging of ponds, water canals, and trenches

5. Excavator:

An excavator is a heavy machinery consisting of a hydraulic crane-like boom with a metal shovel that has sharp prongs on the end used to dig and crush material on a pond construction site. The driver’s cab is on a rotating platform, making the machine more maneuverable and mobile through its wheels (wheeled excavator – image A) or heavy-duty tracks (track/crawler excavator – image A).

It is the main machinery used for digging small and medium ponds. During pond digging the machine scoops earth using its shovel and piles it in the region where the dike is to be constructed or loads it into a dump truck or lorry for transportation.

6. Trencher:

When trench digging becomes labour and time-demanding, you may want to resort to a faster and more efficient way of taking water and electricity into the site. Then comes the trenchers.

Aquaculture trenches are used in underground piping and channels. There are four major types of aquaculture trenchers:

- Wheel trencher (image B): used for digging deep narrow trenches to burry water pipes and cables;

- Chain trencher (image A): used for digging wide deep trenches for water canalisation;

- Micro trencher, portable trencher, and manual trencher (image C): these are light and handy equipment for manual trenching;

- Tractor-mount trencher (image D): like its name, it is a mountable chain trencher having a tractor cabin.

D. Grading and compaction of construction site roads

7. Motor grader:

After all the felling, removal of large rocks, and off-rooting of trees on the site, You will need to flatten the site especially your road paths to facilitate the movement of workers and vehicles during and after construction works. A suitable Road pattern needs to be established including motorways, slip roads, walkways, service roads leading to buildings and ponds. This is when a motor grader comes in.

It is essential to the process of building a road – It flattens a rough area of dirt. As it moves along the area marked out for path, it ensures an even grade thanks to its bottom metal plate that flattens the areas it passes over. For more complicated and muddy sites get a tracked grader. The image below shows grader variants:

- Image A: New CASE Precision Grader Blade on Track Skid Steers – used in muddy pond construction sites

- Image B: Wheeled motor grader without front bucket – used mainly for leveling

- Image C: motor grader with front bucket – a blend of wheeled loader and grader on one machine.

- Image D: Mini motor grader – used to level in the ditch of very small ponds.

8. Soil compactors (drum roller, rammer, vibrating plate compactor)

If you have once worked on a construction site before, you will notice that newly paved roads become very muddy and difficult to use after leveling, especially after rainfall. This is because, after leveling, the ground still contains tiny holes (porous) which gives a chance for rainwater to penetrate into the loose soil and form mud. To avoid this, the soil should be compacted.

There are three types of compactor equipment: rammers, plates, and rollers. Rammers (image E) and plates (image F) are typically smaller and exert less pressure. On the other hand, a dirt roller compactor (drum roller) covers a wider area on the pond construction site and uses its massive weight to compress/press soil and other loose materials.

There are two types of drum rollers based on their drum’s surface nature: smooth rollers and padfoot rollers. Rollers provide static pressure and use vibration to compact loose materials. Based on the number of drums, we may break rollers into single drum rollers (image A) and double drum rollers (image B). If you have to compact very narrow surfaces, for instance within a fishpond ditch, opt for a hand-held single drum roller (image C) or a hand-held double drum roller (image D).

Coming in various sizes and configurations, vibrating plate compactors (image F) can range from 100 to 300 pounds, featuring the largest plates that can produce up to 10,000 vibrations per minute.

Rammers (image E), sometimes called trench rammers, are small, hand-operated compactors. Because of their small size and weight, teams use them in water trenches and pond ditches. They may be static or vibratory. For more information on earthen ponds read this article.

Leave a Reply